The Spitfire Spares Mk IX Spitfire

Welcome to the Spitfire Spares Full

scale replica page

1

2

3

4

5

Substantial upgrading of the original Static

steel frame. This was designed by a professional with lots of maths.

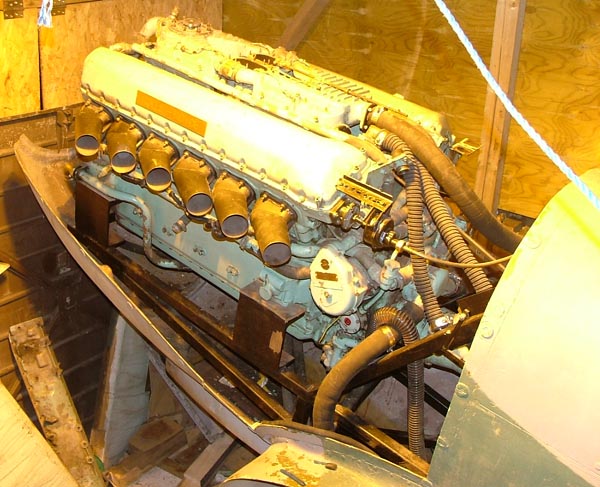

Engine bearer in place ready for the Meteor

From Tank Engine to Spitfire !!

Finally we have

fitted to engine 04/02/07

Progress ought to be a bit more rapid

now, famous last word's.

The blue pump mounted to the front of the engine

is the Hydraulic drive for the prop. Meteors do not have reduction gear.

More Picture's added 5th march

2007 Fitting the exhaust stub's.

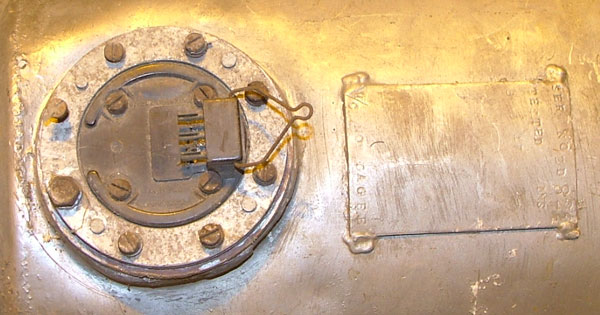

We have sorted the oil tank you can see it in the

pictures behind the fire wall in front of the instrument panel. We also have a

fuel tank, I bought it a couple of years ago with this job in mind and it fits

like a glove. I am mounting it behind the firewall above the oil tank. It has

two fuel outlets, perfect, and is also the right depth. The best thing of all it

has a fuel sender and itís a 38 gallon tank, it's Perfect, not a clue what's

it's from but it's dated 1947. I actually have a 38 gallon smithís fuel gauge. I

havenít got the correct 37 gallon, thought 38 was near enough. Looks allot

better now we have got rid of the air intakes and cooling outlet. We are going

to get good quality hose to connect the water, oil system and fuel. The great

thing about the hydraulic prop drive is that you can turn it off. The prop will

operate from the throttle as in the real deal and can be stopped completely.

This way we can run it at shows without all the worries of chopping someone's

head off. Shouldnít cost anymore to insure than a vintage car. Hoping to show

her off at Popham this summer. Lots to do yet

The Fuel tank

Updated 10 MARCH 2007

Having discovered the Stubs were

fabricated facing down instead of up they have been put right and the

cowling offered up for fitting.

UPDATED 27/05/07

The engine to tank connections have been

completed. The flow of coolant is reversed through the carb manifold and the

rear head outlets and carb manifold flow directly back to the tank.

UPDATED 2106/07

Fuel tank rough first fitting

Note the oil tank below the fuel tank. There will

be heat proof matting on the oil tank and several layers of high impact foam.

Water tank sealed in. The fuselage will receive a

complete make over when the mechanics are done so don't worry about the rough

fit.

Fuel tank final fit a bar with padding will be

welded in behind the fuel tank to seal it in place.

Note some of the instruments have been threaded

through from the engine ready for panel fitting.

The cockpit will be completely re- done, its a

bit rough at the present. Note the high impact rubber under the fuel tank, there

is a layer of heat proof material over the oil tank although we don't expect any

heat problems with the oil due to the limited running time.

The engine with all oil and water connections in

place. The engine will be cleaned and repainted in black with some original

Merlin rockers

You can see the start of the throttle linkage at

the top of the engine mount. Its the tube on the triangular brackets.

Note the oil pressure gauge sender unit in place

below.

UPDATED 30/06/07

Fuel tank final fix, throttle in place, we had to

use a P47 Thunderbolt throttle as we don not have a genuine spitfire one at this

time. The rudder bars are in place to carry the pedals. Note the top and

underside of the fuel tank is lined with high impact foam. High impact foam to

lesson the vibration to the instrument panel fixed around the bulkhead.

Fuel tank, Oil tank, Throttle and rudder bars all

in place.

Throttle in place.

Rudder Bars, you can see the fuel lines running

out from the bottom left and right of the fuel tank.

UPDATED 05/07/07

Throttle linkage complete and

working. It may not look pretty but it works.

Here is the radiator neck finally fitted to the

carb cooling manifold, this will be connected to a header/overflow pipe

Original stick being fitted

UPDATED 10/07/07

Rudder bar and pedals in place

Rear of the rudder bars. The two holes in the

cross member will have threaded bar attached with solid bar running to the rear

wheel and rudder.

UPDATED 26/07/07

One part of My MKVIII Replica I want to keep as

original as possible is the cockpit. The rev counter was a challenge. The meteor

has an electric generator to drive the rev counter, the original Spit was of

coarse mechanical. The original rev drive ran off the cams at a 4:1 reduction,

i.e. 1/4 engine speed. So I needed a 4:1 reduction gearbox that would fit the

meteor drive for the Rev electrical generator. Tall order!!!! I have a few

generators that work the opposite way they convert mechanical drive from the

Merlin into electrical drive, out of curiosity I took one apart, what a result

they contain a 4:1 reduction gear box. Having removed the armature, I connected

the mechanical drive to the rev counter and gear box and put an electric drill

on the gear box. One problem the meteor rotates in the opposite direction

to the Merlin, that's when luck was really on side for a change, the rev counter

works quite happily regardless of which way the gear box spins. I guess they

designed them that way for different handed engines, I know this kind of rev

counter was used in loads of other RAF types with different engines. Here

is the unit connected up with the flexi drive cable attached.

UPDATED 21/07/07

Tail wheel completed and fitted to rudder bars,

it works!!! The rudder has had lots of

fabrication to fit so that it works. The rudder,

tail plane and elevators will be removable

for transport. Some of the panels have been

prepped for painting.

Instrument panel being wired the fuel gauge now

works with the fuel tank sender

Manual Rev counter drive conversion in place, top

cowling has been test fitted.

New Rudder pedals fabricated from steel the repro

alloy ones snapped and were like a

honeycombed inside.

1

2

3

4

5

|